DELTA-LEANING RECUMBENT TRICYCLE Aug 2017 - Mar 2018

Human Powered Vehicles Club, Fairing Subteam MemberUC Berkeley, CA

My contribution

Designed (1) an aerodynamic fairing shell to increase vehicle speed and (2) a “grocery” basket to carry a carton of eggs. Assisted with carbon fiber frame layups, bike part machining, and bike assembly.

Completed carbon fiber fairing

About the vehicle

For the ASME (American Society of Mechanical Engineers) E-Fest West Human Powered Vehicles 2018 Competition, we built a leaning tricycle. The design allowed the vehicle chassis and rider to lean into the turn while keeping all three wheels on the ground. The competition evaluates the vehicles based on their design, innovation, and performance both in the sprint event and in the 2.5 hour endurance relay event involving slalom, speed bumps, and the ability to carry eggs without breaking them.

Demonstrating the delta-leaning mechanism for turns

Awards

- 3rd place overall

- 2nd place Design Award

- Best Craftsmanship Award

The fairing

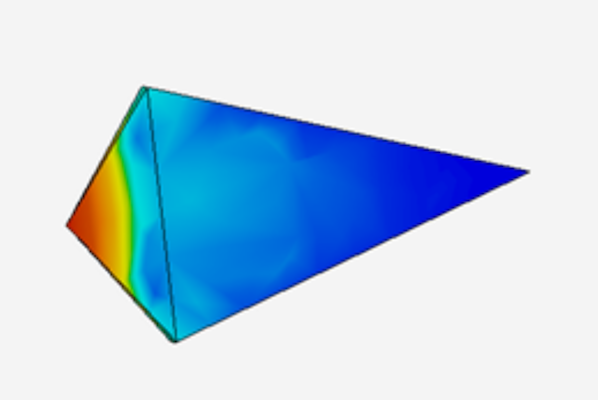

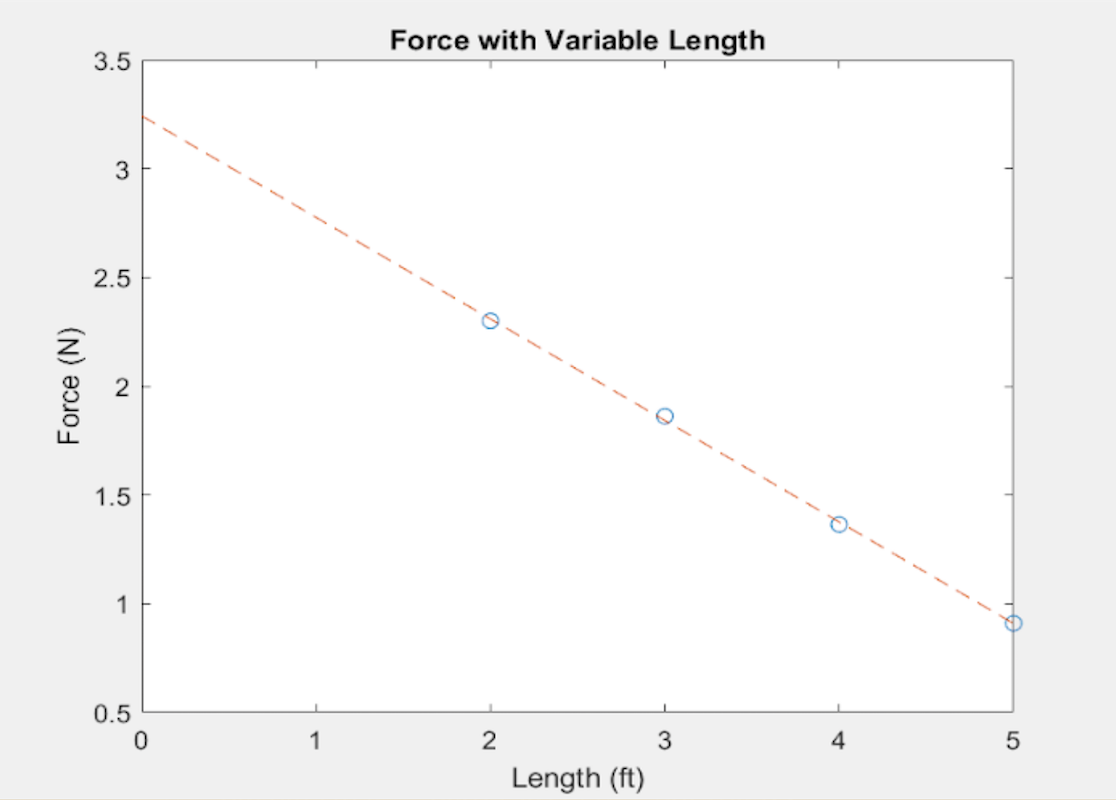

I worked in a team of four to design the fairing. We selected a rear fairing since the bike would be racing at approximately 20 mph, so a lighter rear fairing outweighed the aerodynamic advantage of a full fairing. I used SolidWorks and ANSYS to create 3D models, simulate fluid flow, and perform FEA testing to determine the optimal length and shape of the fairing. I also participated in all stages of the manufacturing process, creating the fairing from carbon fiber fabric and layering the fabric in a foam mold to create the final fairing.

ANSYS simulation of fairing test model

During the competition, we found that the bike raced faster without the fairing and removed it. Our fairing design did, however, help earn us the design award.

Design highlights

- Lightweight carbon fiber fairing

- Height and width match exact dimensions of the rider and frame to reduce drag

- Shorter length for lighter fairing

The basket

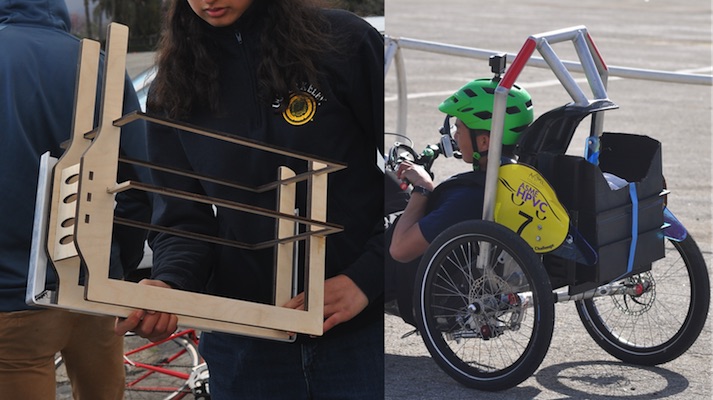

The endurance event in the competition involved carrying surprise “groceries” for four laps over speed bumps and slalom stretches. Since the grocery items were only revealed on the day of the race, the grocery basket had to be built to carry fragile or heavy items that fit within the given size and weight constraints. The groceries were four cartons of eggs, and only one egg broke.

The Endurance Race at ASME's 2018 E-Fest West Competition

I independently designed and built the grocery basket. It consisted of a box held by a laser-cut wooden frame mounted to two aluminum flat bars (that I shaped and bent by hand), which were bolted to the acrylic flags on the side of the bike (where the yellow number 7 is). The entire grocery basket was spray painted black.

Laser cut basket frame (left) and finished basket (right)

Design parameters

- 13” x 8” x 15” maximum grocery size

- 5.5 kg maximum grocery weight

Design highlights

- Mounting points, location, and orientation selected to to minimize shaking and help transport fragile items

- Box frame designed to assemble and hold without glue, screws, etc.

- Padding inside box for safe transportation of fragile groceries

- Box opening designed for speedy loading and unloading

- Materials selected to minimize weight, maximizing speed

- Three-bolt basket mounting to ensure quick removal during the race

Our team and tricycle at the ASME competition

Additional photos from the design process

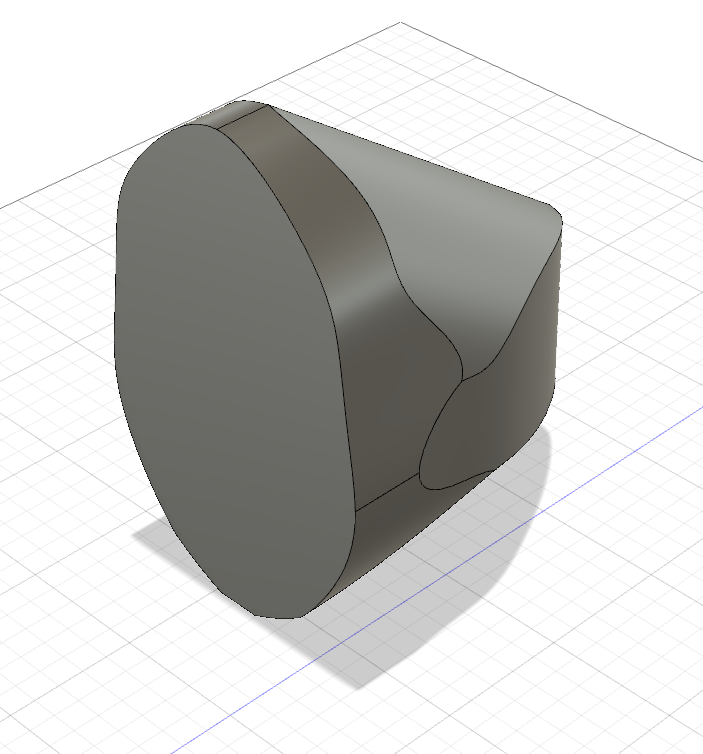

Autodesk Fusion 360 model of fairing

Graph of drag force versus fairing length based on ANSYS tests

The Sprint Race at ASME's 2018 E-Fest West Competition