TENSEGRITY ROBOT May 2017 - Aug 2017

BEST Lab, Research Intern under Prof. Alice AgoginoUC Berkeley, CA

My contribution

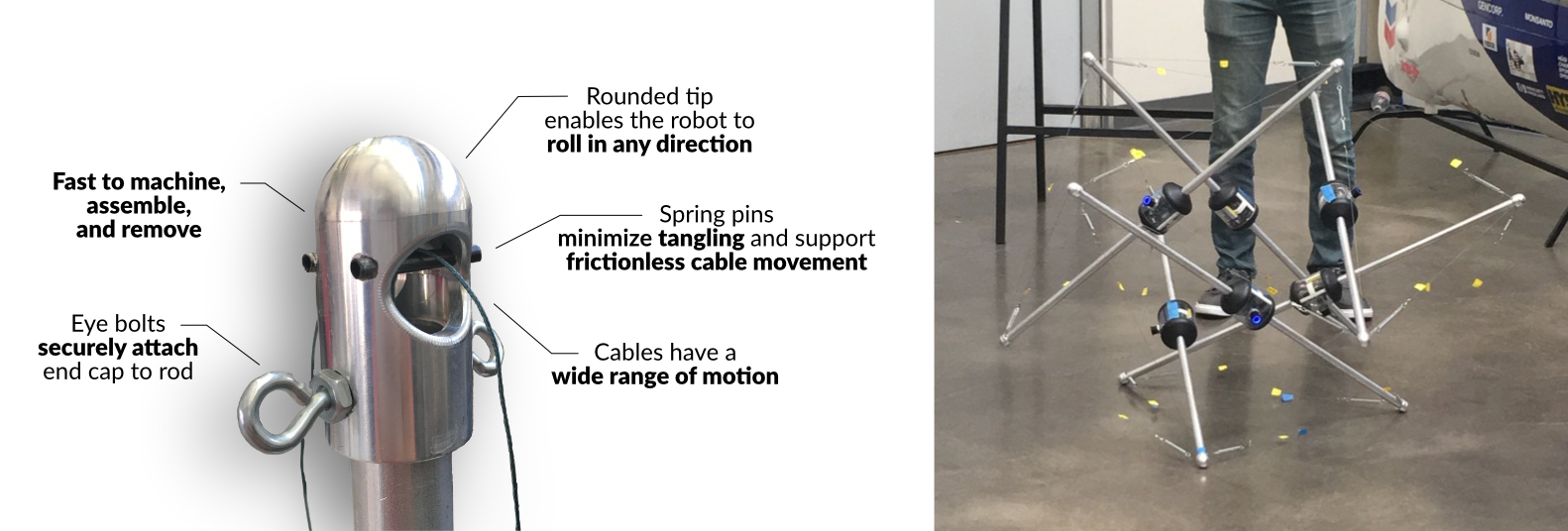

Designed and built new end caps for each rod of the 6-bar tensegrity robot, minimizing friction while increasing durability and mobility. Worked with tensegrity team members and my Ph.D. student mentors to ensure that my creations complemented the functionality of their components.

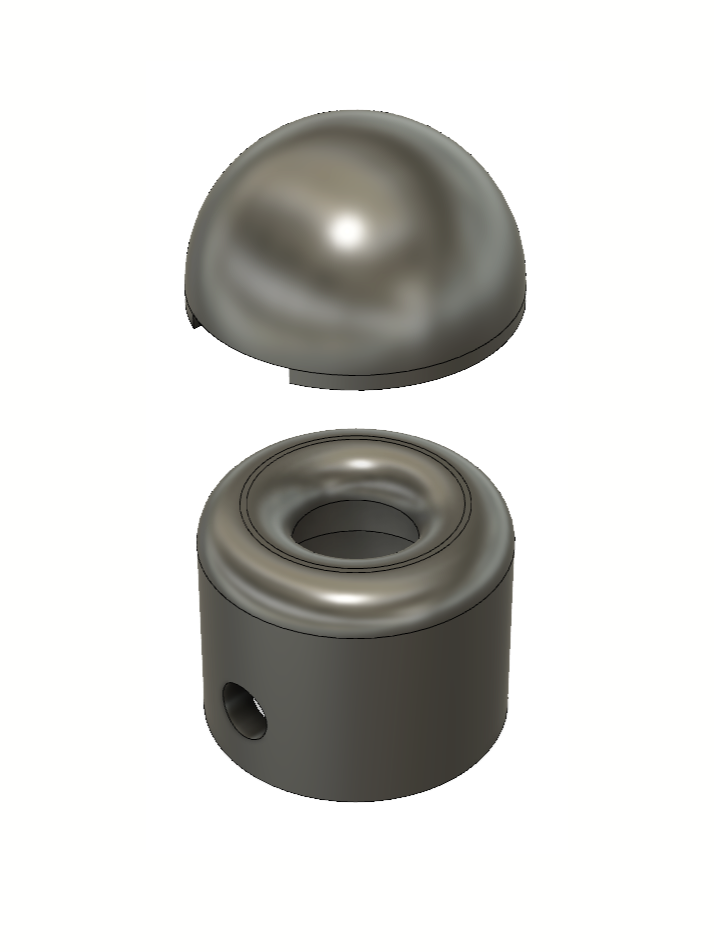

Left: Final end cap design

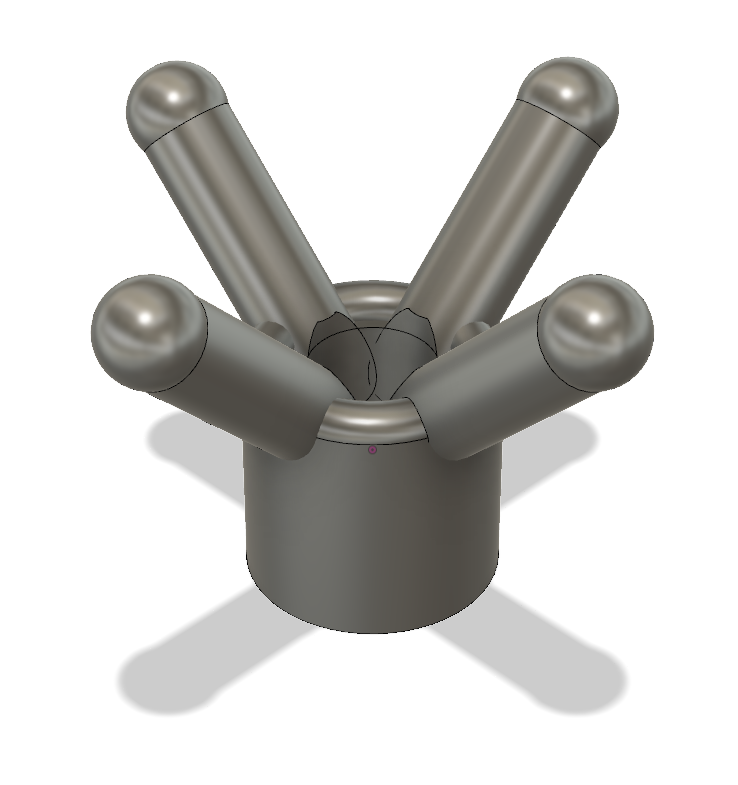

Right: 6-bar tensegrity robot with end caps at the end of each rod

About the robot

BEST Lab’s versatile 6-bar tensegrity robot is intended for use in search and rescue and as a rover for Jupiter’s moon Titan. The robot moves by adjusting the tension of cables running from inside a given bar to the end of an adjacent bar, causing the robot to change shape, shift its center of mass, tip, and roll over.

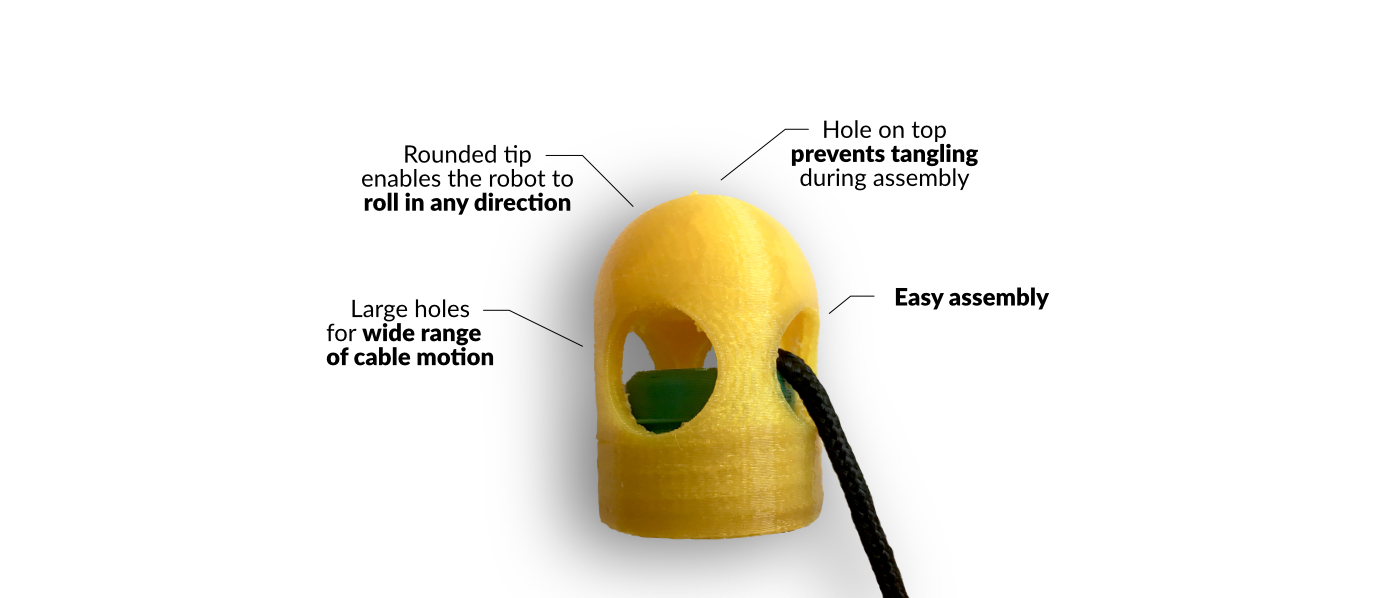

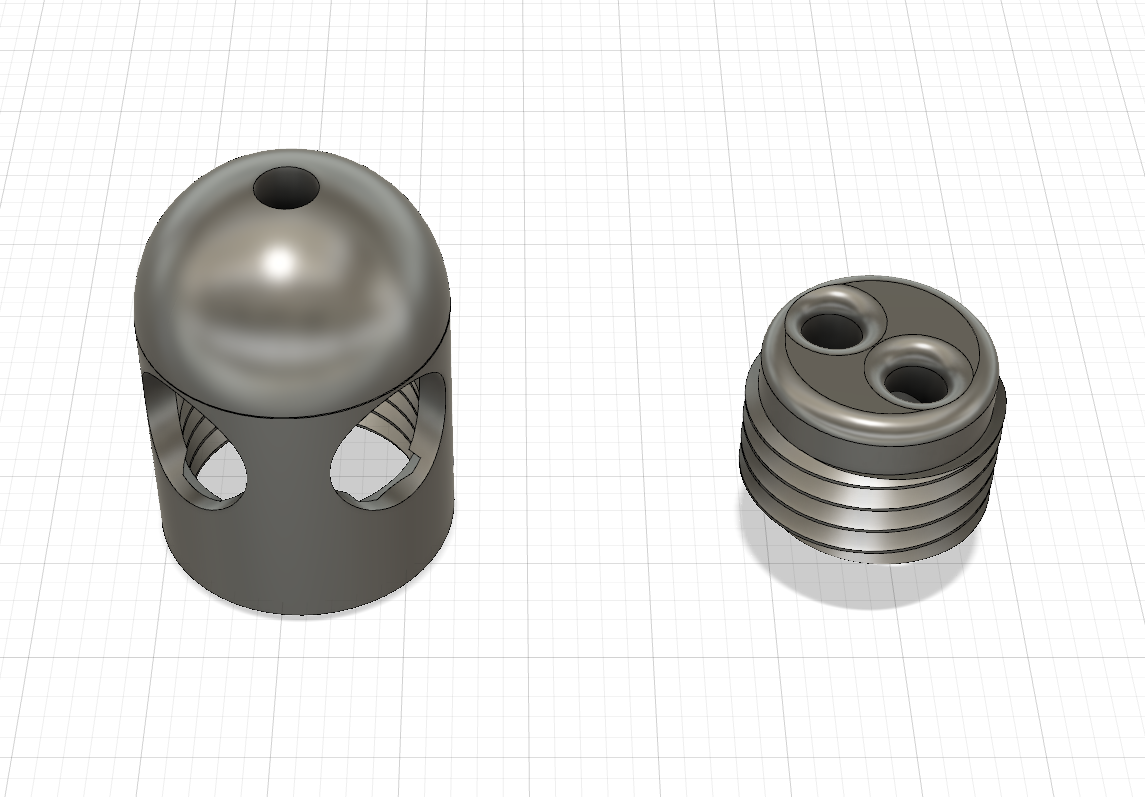

End cap: intermediate version

From initial prototyping (in Fusion 360 and FDM 3D printing) and group feedback, I learned that the end cap tip must be round so as not to impede robot motion and that a cover attached to the end cap with tiny screws or bolts was difficult to accurately machine. I designed this intermediate version to solve those problems. Because preventing the cables inside the rod from tangling was an important design factor, the inner (right) piece of the end cap was press fitted onto the rod and contained two holes to separate the cables. The outer (left) piece would then be screwed on.

Intermediate 3D-printed prototype

Prototype drawbacks

- Difficult to machine threads and rounded edges of holes on inner part

End cap: final version

This design, which originated with graduate student Alan Zhang, was ultimately selected because of its simplicity, ease of manufacturing, and ease of assembly. I learned that these three components are key in handmade projects, almost as important as optimizing design functionality.

I conceptualized, modeled, and prototyped all aspects of all previous designs. For this final design, I modified the holes and placement of the spring pins so that the cable had a wider range of motion and touched only the spring pins for minimal wear.

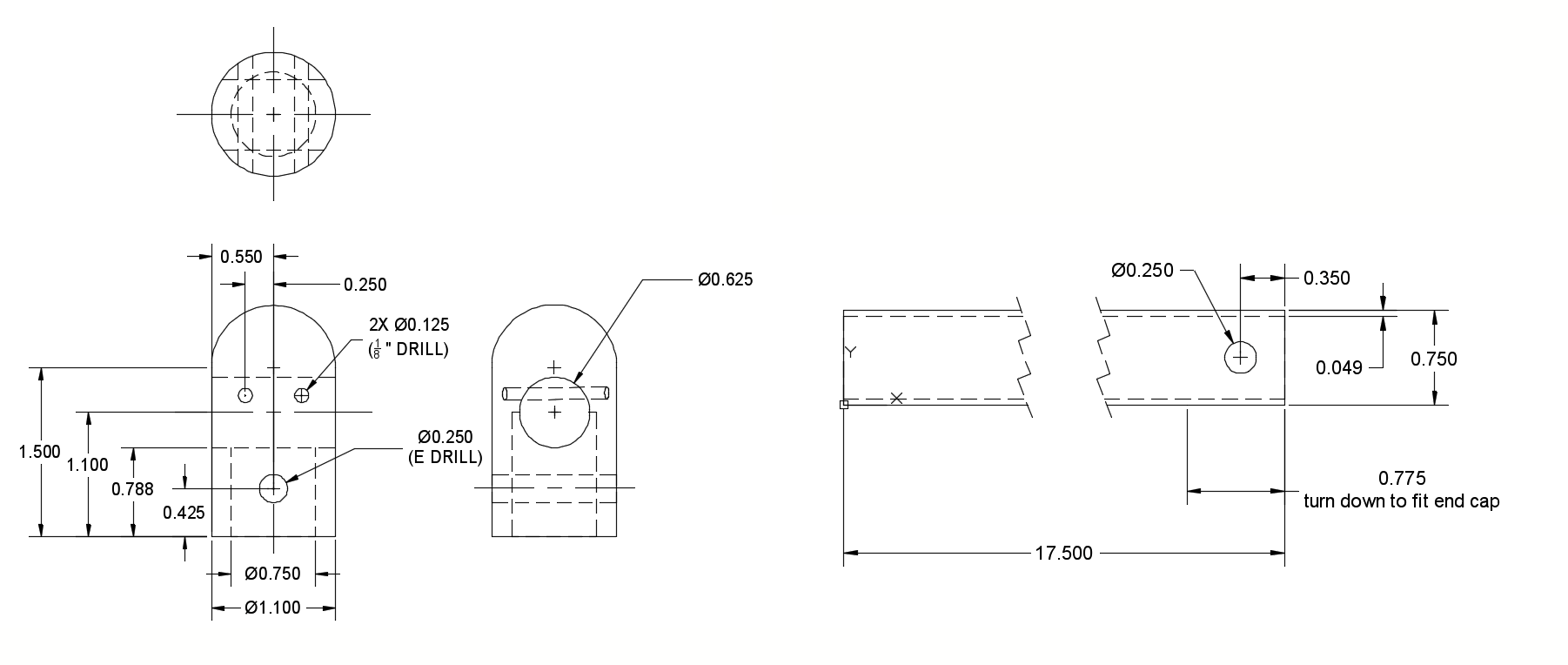

Dimension drawings of final end cap and rod

Additional photos from the design process

Fusion 360 models of a several intermediate end caps

FDM 3D printed end cap prototypes